Innovasys designs, builds and programs fully integrated crane control and drive systems for the industrial production crane markets. These markets include the lumber industry, co-gen power facilities, bulk material and marine handling and the oil industry, with systems as large as 1,200 metric ton. We have developed drive firmware, as well as PLC control algorithms, to give our customers precisely the functionality and performance they require. We integrate production crane applications with our common DC Bus Multi Drive Systems. We have integrated 4,200A systems, implementing as many as 35 drives, and over 14,000HP for large cranes in the oil industry. Innovasys has drive and motor experience for a variety of applications including, but not limited to:

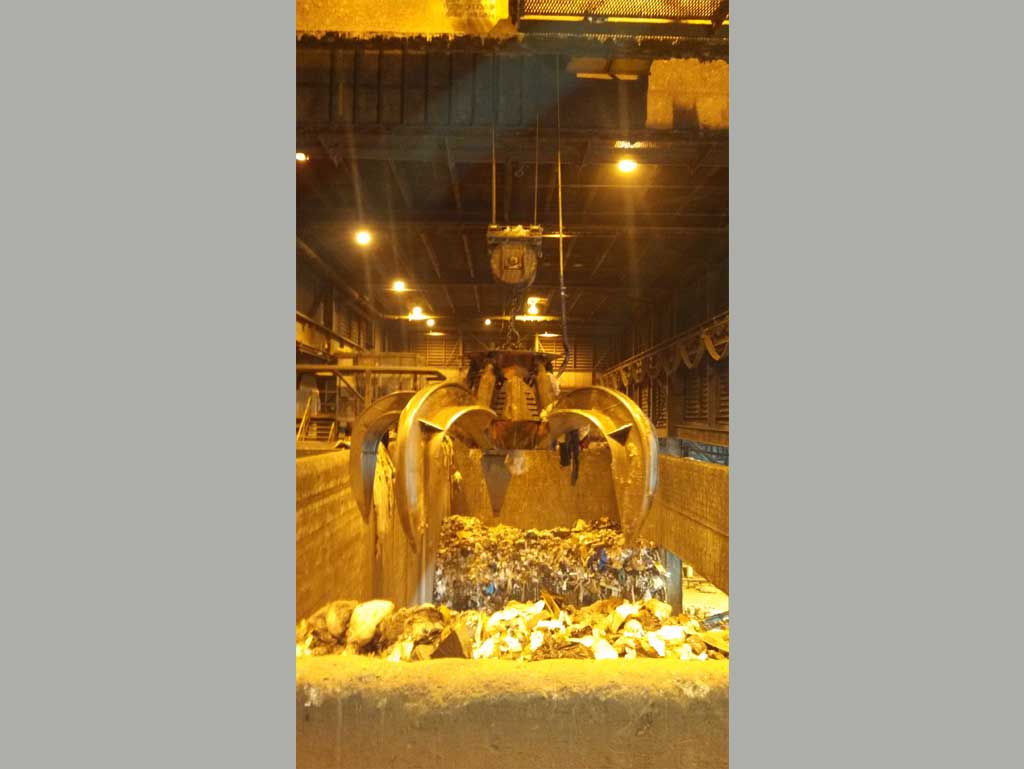

- Ash hydraulic grab cranes

- Refuse hydraulic grab cranes

- Refuse dual hoist grab cranes

- Portal logging cranes

- Straight track inter modal cranes

- Coal ship loaders

- Apron hoist cranes

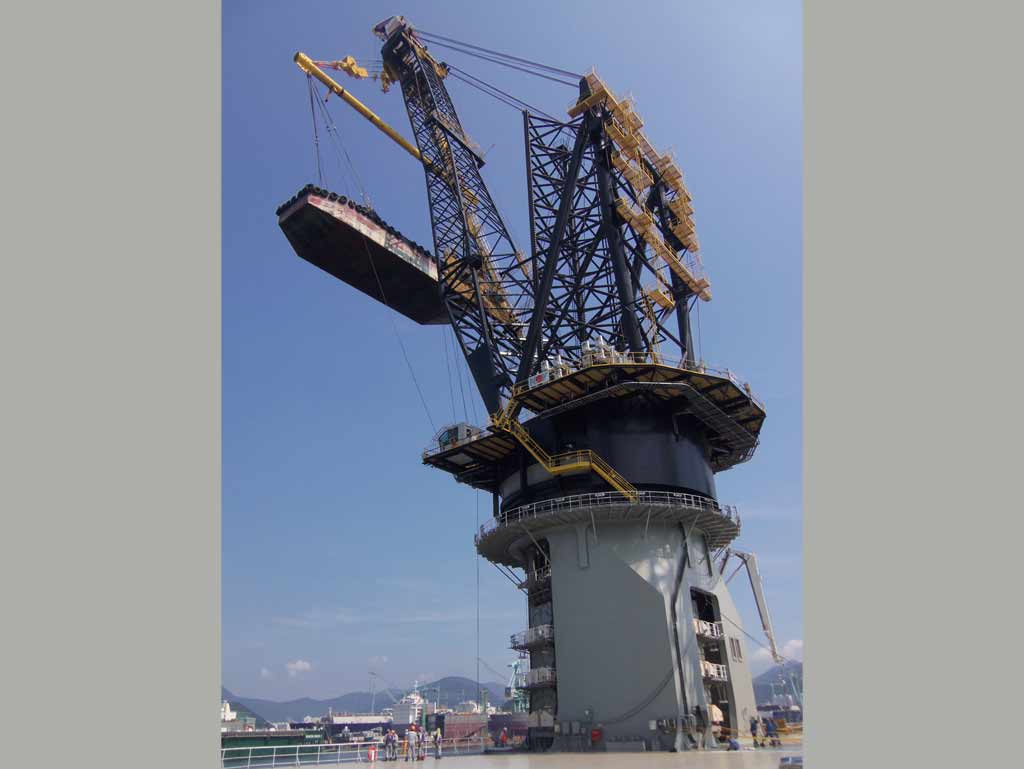

- Derrick cranes

- Telescope cranes

- Offshore marine boom cranes

With ABB’s active regenerative common DC bus technology, Innovasys builds dynamic drive systems. The drive control systems enable energy savings by feeding the braking energy of the motor back to the network, or by recirculating the energy across the Common DC Bus. Innovasys has designed many crane systems which recirculate, or regenerate, electrical power with only parasitic losses being wasted. For crane generator supply applications, a 12 pulse dual supply is integrated with air cooled, or water cooled resistor banks for excess regeneration power, while still sharing power across the DC bus when applicable.

Logging Portal and Circle Track Cranes

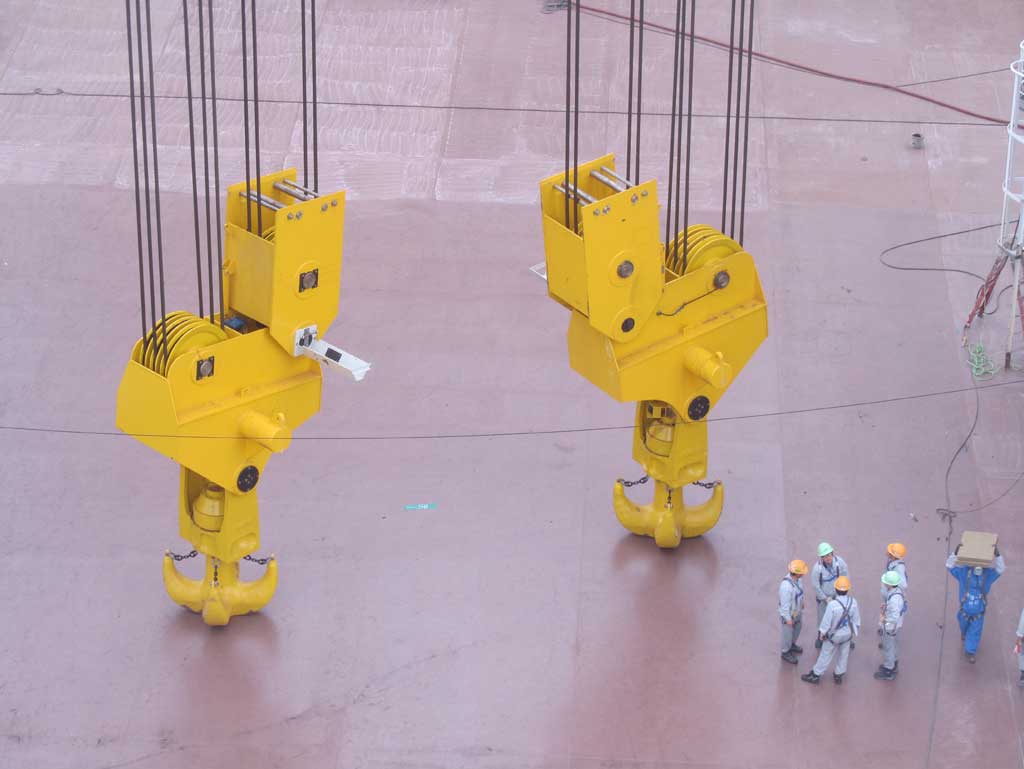

1,200MT Windmill Crane

Testing

4000A Common Bus with 1200kw Resistors

6 200HP Swing Motors for 1,200MT Derrick Barge

1,200MT Derrick Barge Main Hoist